The release of the ALT-2010 laser was truly a big deal for Applied Laser Technology. After all, this was its first product and it had lined up its first sale with an industrial company that planned to use the device to strip insulation from flat computer ribbon cable. But the laser manufacturer had the vision for something bigger in the future: expand the potential for laser materials processing to include multiple materials and processes with a single laser system.

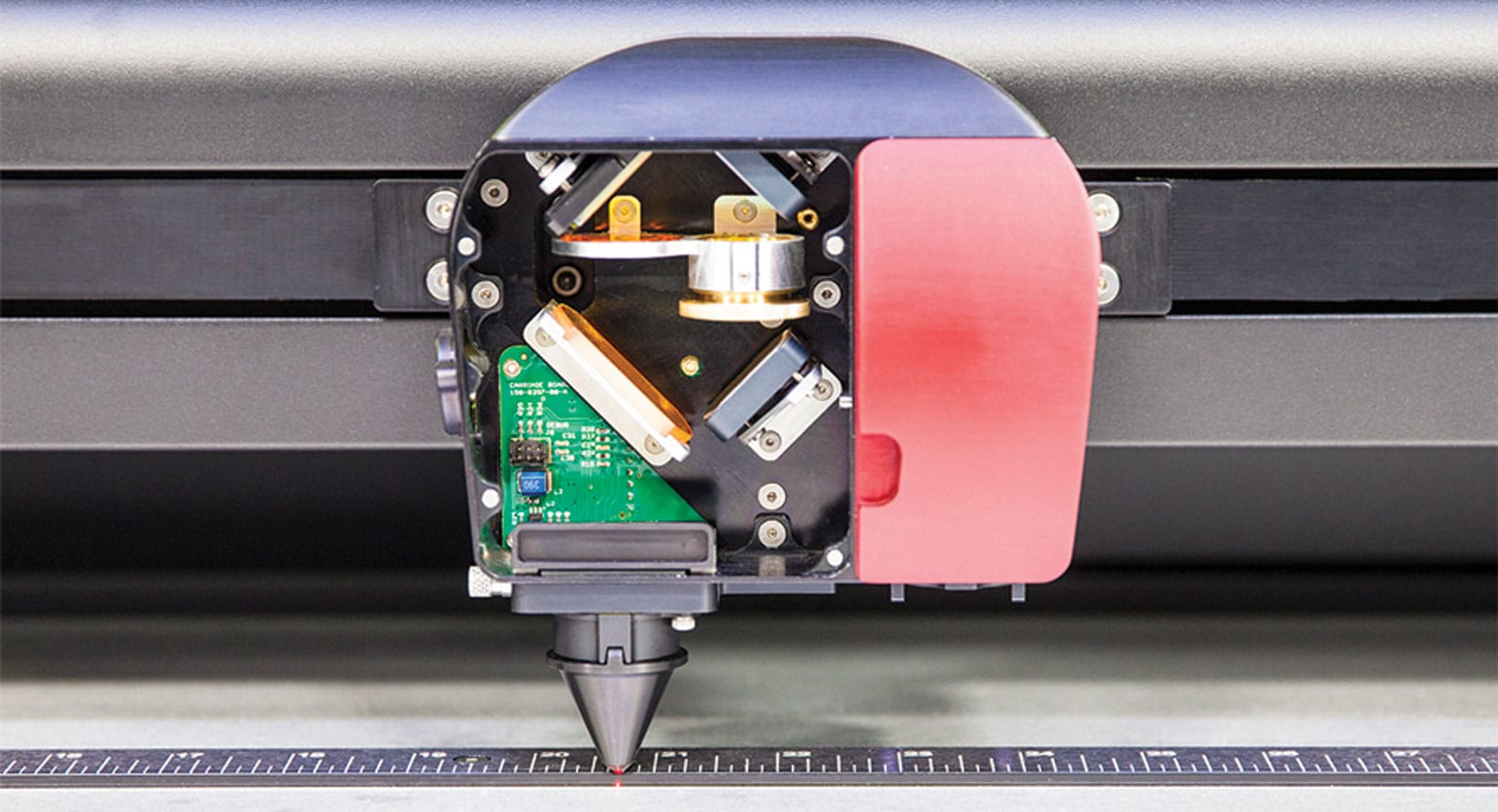

Twenty-eight years later and now going by the name Universal Laser Systems, the company recently was awarded a patent for its MultiWave Hybrid™ technology that combines beams from multiple lasers into a single, hybrid laser beam. This offers improved laser material processing flexibility and adaptability by providing users compatibility with the widest range of materials while offering opportunities to combine different laser power levels and wavelengths. The new technology can be used in manufacturing, material science and product development.

“This technology has the potential to produce new and novel methods of processing materials with laser energy by combining multiply wavelengths of laser energy into a single beam, which can produce reactions from materials not seen or possible when only one wavelength is used,” said Chris Risser, the Scottsdale-based company’s director of product development.

While it took Universal Laser Systems 28 years to roll out this prime example of its vision, along the way the company became recognized as a world leader in laser materials processing while opening subsidiaries in Vienna, Austria, and Yokohama, Japan. The company has a stake in an industry with an expected compound annual growth rate of 6.13 percent between 2016 and 2022. The market research firm MarketsandMarkets estimates the laser processing sector will reach a value of $9.75 billion by 2022.

Helping Universal Laser Systems grab a share will be the MultiWave Hybrid, which allows users to control lasers individually and combine them in any proportion to create a number of desired effects on various materials. This make it ideal for processing many materials, such as industrial films, engineering plastics, laminating adhesives and composites. It also keeps costs in check by eliminating the need to purchase new laser systems for each unique application.

The company already has become the leading provider of CO2 laser technology solutions, with one of its solutions installed in every country in the world for customers ranging from small, family-run operations to highly automated Forbes Global 2000 companies. Its design philosophy focuses on developing innovative technologies and modular components to deliver the best customized laser material processing systems for the broadest range of materials.

The company delivers more than 1 million different laser system configurations using patented technologies — more than 30 are detailed through its website — and advanced products. From the development of laser sources and advanced software and beam delivery systems to an extensive investment in the research of laser materials processing science and applications, Universal Laser Systems provides innovative, cost effective, flexible and scalable laser material processing solutions.

Photo Credit: Applied Laser Technology