Pilgrim Aerospace Fasteners implemented the first phase of its automation plan with the help of Arizona Manufacturing Extension Partnership (Arizona MEP), In-Position Technologies (IP Tech), and the Arizona State University Polytechnic campus. Pilgrim specializes in military and aerospace threaded fasteners. The automation plan is designed to improve efficiency to meet growing demand for its screws, bolts, special fasteners, and other unique hardware. Pilgrim consolidated its Rhode Island operations to Chandler, in 2018. Arizona’s business-friendly environment and relocation services provided by the Arizona Commerce Authority were key incentives for Pilgrim to choose the state for its operations.

AZ MEP Client Advisor Connects Pilgrim to Automation Partners

A few years ago, Arizona MEP worked with Pilgrim on a successful value-stream mapping project on one of the Pilgrim’s most profitable parts. The relationship continued with Arizona MEP senior client advisor, Tanya Perkins, meeting with the leadership team regularly to discuss the goals and strategies for the company and its current situation. One of Pilgrim’s goals was to implement more automation and robotics at the facility. Based on a past project with another client who had similar goals, Perkins was able to connect Pilgrim with IP Tech, a licensed dealer for Universal Robots used in manufacturing.

In-Position Helps Pilgrim Select the Right Solution

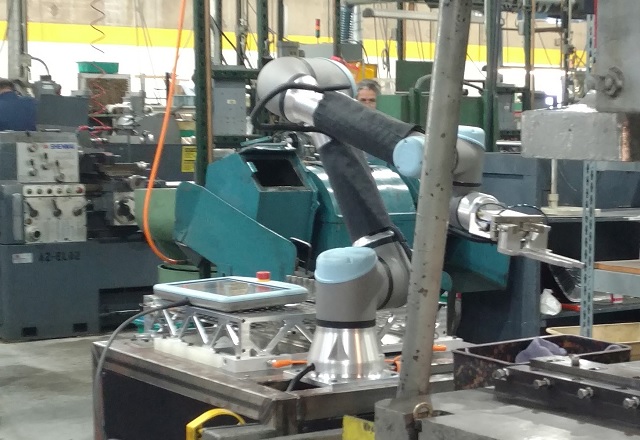

The local IP Tech representative met with Pilgrim to learn more about the company’s operations and automation goals. At the meeting, they discussed the equipment and processes used, the type of parts supplied, and the typical order size. The meeting ended with a demo of a robotic arm used for pick and place. “The rep from IP Tech set up a robotic arm demo in less than half an hour and programmed a pick and place in less than two minutes,” said Jason Grove, Pilgrim’s chief operating officer. “Through the demo, we saw how the robotic arm could work alongside an operator to perform repetitive tasks while the operator focused on checking quality, doing the necessary paperwork, and setting up another machine.”

ASU Polytechnic Supports the Implementation

During this initial phase of the company’s plan, Pilgrim planned on installing two Universal Robots (UR5E): one in a CNC cell and the other in the hot forging department. IP Tech recommended that Pilgrim work with students at ASU Polytechnic to help with the engineering and system programming needed for implementation. As part of the implementation, students worked on two capstone projects to design and build the mobile stands used to support the robotic arms and programmed the robotic arms to talk with the CNC machines and to each other.

“We did two projects with ASU Poly. We did a capstone project for seniors, which spanned over two semesters. They worked on the robotic arm in the hot forging department. They built a stand and did the engineering needed. At the same time, juniors started a one-semester project to complete the engineering drawings and design work for the robotic arm in the CNC cell,” said Jason. As a result of the project, Pilgrim hired three of the students as employees after they graduated.

Robotics Supports Growth Plans

“The robotic arms were implemented to make us more efficient, reduce lead times, and support our growing business,” commented Jason. The success of this project has given Pilgrim a successful blueprint for adding an average of two robotic arms per year in addition to adding more CNC machines and expanding its Chandler facility. With the connections made through Arizona MEP, IP Tech and ASU, Pilgrim has aligned the resources necessary to implement the company’s multi-year automation plan.